Becker Smartsense

Becker Mining South Africa’s range of safety and communications systems encompasses the high-accuracy Becker Varis Smartsense gas monitoring system, which has been designed for use in industries where the presence of gases may pose a safety or health risk to employees and the environment.

Becker Mining South Africa deployed a mine wide Environmental monitoring system at one of the leading Platinum supplier’s incline sites consisting of 38 Smartsense controllers, ensuring real time monitoring of the working environment for personnel safety. In these environments, it is important to monitor gases emitted into the atmosphere in real time and have a reliable system to take immediate, automatic action to eliminate the possibility of poisonous environments, as well as explosions.

The installation consisted of combination gas Smartsense controllers, monitoring Oxygen (O2), Carbon Dioxide (CO2), Carbon Monoxide (CO), Methane (CH4), Hydrogen Sulphide (H2S) and Nitrogen Dioxide (NO2). In addition to monitoring the specific gas concentrations, all the Smartsense controllers have integrated ambient temperature, humidity and barometric pressure monitoring, ensuring the continuous monitoring of all relevant environmental conditions

The deployment of the mine wide monitoring system was completed in a record setting deployment time frame for the mine, reducing previous deployment schedules by more than 75%. The rapid deployment capability mitigated risks associated with possible unsafe working environments encountered in the mining areas.

The Smartsense system conforms with stringent quality, safety and environmental specifications, and adherence to intrinsically safe (IS) certification means this system can also be safely deployed in hazardous and potentially explosive areas. The Smartsense unit can be fitted with different gas monitoring heads to suit specific environmental monitoring needs.

Gas monitoring systems in the mining sector are used to detect the presence of flammable and toxic gases that can cause serious irritation to the eyes, nose and throat, and some gases, when inhaled, can cause unconsciousness and even death. Gases known as asphyxiants displace oxygen in confined areas underground, causing difficulty in breathing and even suffocation. Gas monitoring solutions ensure an oxygen- rich environment for workers, enhancing productivity and safety.

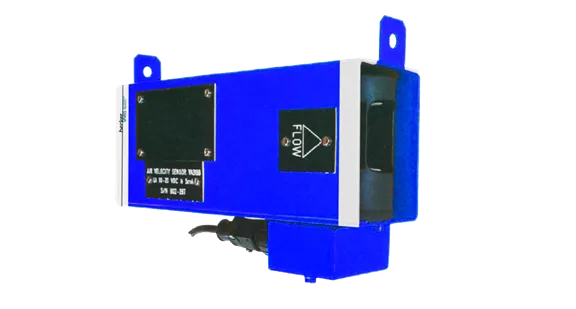

All features of the Smartsense device are integrated into one compact unit, which is an important advantage over conventional monitoring systems. There is no need for complex cable connections, troublesome programming or difficult calibration as the Smartsense unit can be calibrated during opperation. Additional analogue/digital input ports provide compatibility with other devices, to accommodate a plant’s

expansion requirements. For example, an additional sensor connection point could be used to measure airflow.

Smartsense SSFM-100 gas monitors/controllers allow for localised use, or for implementation into a system-wide installation using industry-standard communication protocols such as Modbus RTU and OPC, or for integration into legacy systems using 4-20 mA signals.

With the Smartsense fixed monitor’s three fully programmable alarm setpoints for alarm and output controls, with a short-term exposure limit (STEL) and time-weighted average (TWA) displayed on an LCD screen that is large enough to view the reading from up to 5 m away, the deployment of the system ensured that each area being monitored had both local and remote alarming capabilities. The mine’s stringent safety requirements were met by ensuring each area works independently, however, all the Smartsense controllers were integrated to a central control facility for remote monitoring. An adjustable backlight made this device suitable for both underground and above-ground applications