ENDIS4.0

The world’s most controllable underground power distribution solution

The ENDIS4.0 series from Becker Mining Systems sets new standards by elevating modularity and connectivity to an unprecedented level. The ENDIS-Compact Station CS4000 emerges as a compelling solution for a switching device that can be utilized across various voltage levels. With its modular design, the CS4000 can be flexibly configured according to customer requirements and adapted to future needs. Becker Mining Systems takes this flexibility and adaptability to a new level with the ENDIS4.0 series. In doing so, the company revolutionizes the industry by providing innovative solutions that meet the evolving technological demands.

Explore more on the ENDIS4.0 page to discover the full range of possibilities.

ENDIS TRADITION

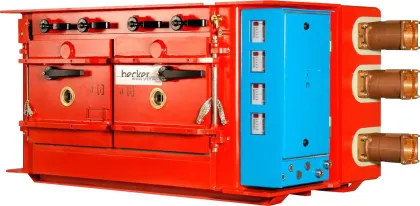

Flameproof Switchgear for Underground Mining Applications

The flameproof switchgears of our ENDIS product range have been developed for use in hazardous areas (Group I - Category M2) in underground mining operations. They are used for energy distribution of electrical equipment in IT AC systems. Based on the requirements, the devices are used as circuit-breakers, motor control devices for switching, controlling and monitoring alternating current (AC) or frequency converter motors and as a lighting system.

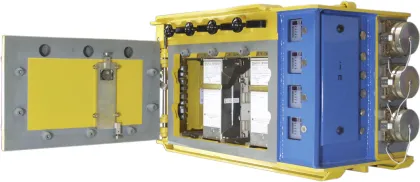

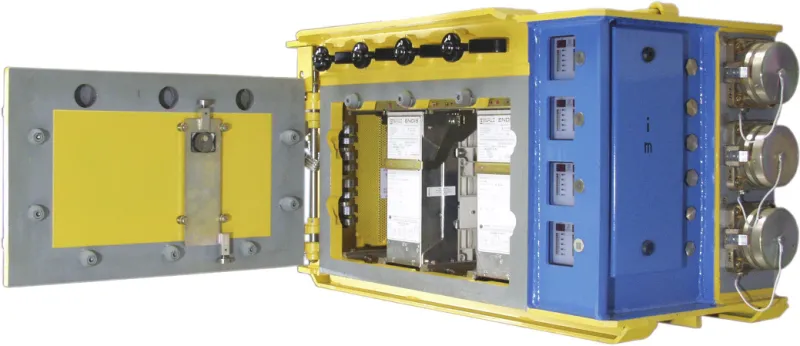

Compact Design

Our ENDIS switchgears have no terminal compartments. Plug-in modules replace switches, contactors and discrete monitoring technology. There are no conventional disconnecting switches. Every plug-in unit is part of the disconnecting device. The power bus with plug contacts for the plug-in modules replaces conventional wiring. This saves space. No additional wiring means saving time and costs. All switchgears have standardised slots, into which any plug-in module suited for the slot type can be inserted.

Modular Technology

Modular technology? That isn't anything special. But ENDIS is. Our modular technology differs considerably from the standard. There is no connection between the plug-in module and those switchgear for power and control lines, which have to be connected manually. The plug-in module must only be pushed into the switchgear and switched on using the disconnection device. In the process, all connections are established automatically. No further effort is required. An appropriate plug-in module is available for every application, whether as a power contactor for a large drive, a double contactor for low to medium power drives (even as a double reversing contactor), insution monitor with lighting outputs or a power switch for medium voltage.

Integrated Control and Monitoring Electronics

No individual monitoring components have to be set manually. A protective module, an electronic unit that assumes all control and monitoring functions of the plug-in module, has been integrated into the system. The plug-in modules can be systematically controlled in parallel via contacts, but also serially using field bus adapters through our MINCOS product families.

Easy Parameterisation

The protective module in the system communicates with the display module in the switchgear via a serial data bus. There, the most important information from the plug-in modules are displayed and all parameters are set and saved as a protection against a voltage loss. The flameproof enclosure of the switchgear does not have to be opened for this purpose. When changing a plug-in module, the values stored in the display module are automatically transferred to the protective module in the system and stored there. A re-entry of the paramters is therefore not necessary.

Plug-In Connections with Disconnecting Devices

In the case of the Endis® switchgear for low voltage, there is no excessive work for wiring and connecting to terminals in tight terminal compartments required. All external connections are created using plug-in connectors. This saves time during the installation. Every plug-in module has a disconnecting device for its seperation from the power bus. The power connector plug system covers the spectrum of main voltages up to 1.1 kV and nominal currents of 400 A. All three desings with nominal voltage 250 V for lighting systems and 1.1 kV for small and large drives have flameproof enclosure type "d" protection when assembled. The assembly of both 1.1 kV designs is very easy and can also be performed underground. Due to the solid, completely screwed construction, the plugs can be reused. Switchgear for medium voltages of 3.3 kV are naturally also available with plug-in connectors.

POWER CENTERS

For Underground Power Distribution

Becker Global America specializes in the design, manufacturing and servicing of customized power distribution equipment to meet special application requirements. Primary voltages up to 35 kV and complete specification designed and manufactured per customer requirements. Becker Mining Systems' longwall electrical solutions are utilized on over 70% of the longwall operations in the USA. The most efficient, highest tonnage-producing mines use our equipment. Our innovative products have made major advancements in mining control and automation. We provide safe, user-friendly systems, enabling higher operating efficiency and increased production. We design, manufacture and commission the electrical system from start to finish. Our longwall power distribution systems range from 1000 kVA to 12 MVA and are in highest demand in the mining industry, having supplied power to the longwall faces for over 30 years.

Arc Guard™ Mine Power Center is the first and only mining arc resistant power center. Becker Mining Systems' patent pending design of arc mitigation open frame equipment eliminates potential arc flash injury and complies with ANSI IEEE arc resistant requirements. It emcompasses all underground and surface electrical equipment and has been independently tested at KEMA US Laboratories in Pensylvania.