Becker Mining Systems completes upgrade projects at Zululand Anthracite Colliery (ZAC) in KwaZulu-Natal.

“These projects involved the upgrade of existing switchgear at the plant substation and the installation of communication, automation and protection systems at the mine’s MacNelly Plant. Becker Mining was also responsible for the design and installation of advancements at the main washing and siding plants, as well as the establishment of a leading-edge control room,” says Frikkie Quirk, Becker Mining South Africa. “These upgrade projects - installed and commissioned on time - have resulted in improved efficiencies, greater productivity and energy savings.”

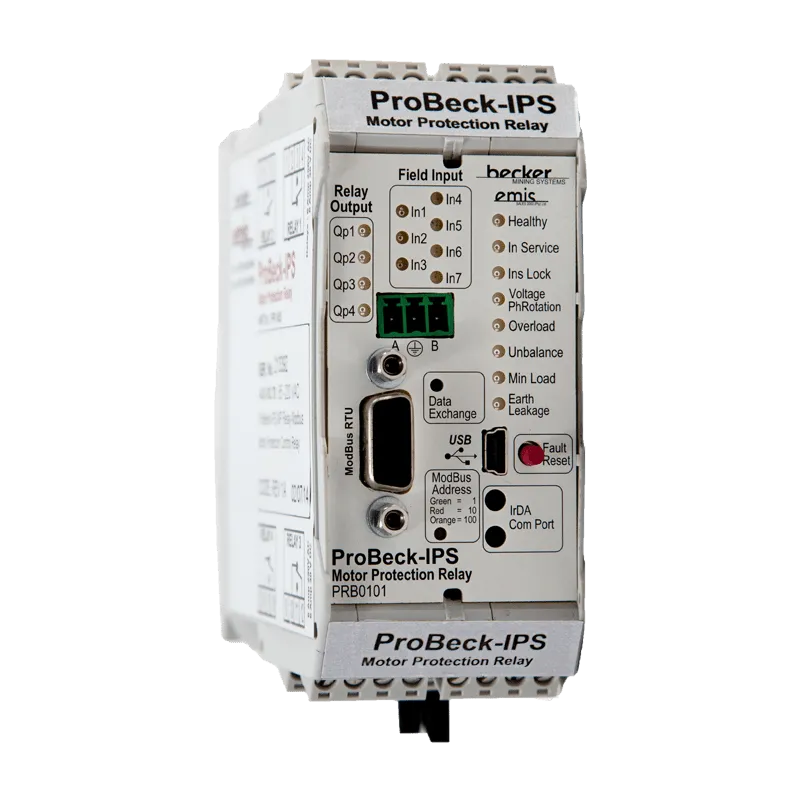

Upgrades to the 11 kV plant substation, which involved replacing outdated equipment with new switchgear with remote switching, ensures a high level of operator safety and system protection. Since the improvements at the MacNelly Plant, there has been an increase in productivity of about 8%. Enhancements at the main wash plant – which was previously operated manually – includes the installation of Becker ProBeck motor protection and control relays. This project has seen an increase in plant efficiency and a reduction in pump replacements, as a result of correct motor protection delivered by Becker. Motors at the siding plant now have an automatic start-up via one start button to PLC and are programmed to stop in sequence. In addition to improved efficiency, an important advantage of the new system is energy savings. The new control room - with an advanced Adroit 10 SCADA system set-up via the Becker Wi-Fi communication - provides full control over production and plant availability.

For more information go to:

[Link zu „Probeck IPS Product Brochure“]